Introduction to Connecting Copper Pipes to Towel Rails

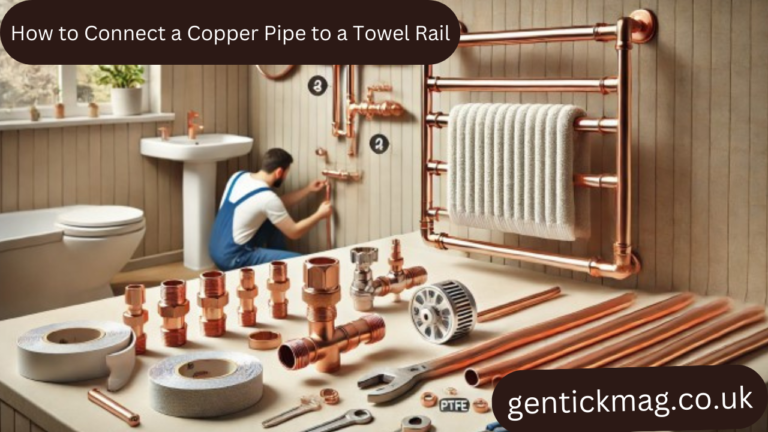

When it How to Connect a Copper Pipe to a Towel Rail comes to introducing a towel rail in your washroom, one of the foremost vital errands is interfacing it to your plumbing framework. Particularly, interfacing a copper pipe to a towel rail may be a common strategy utilized for giving hot water to the rail, guaranteeing that your towels remain warm and dry. Be that as it may, this prepare includes a few imperative steps to guarantee the association is secure and leak-free. This direct will take you through the vital steps to correctly connect a copper pipe to a towel rail, permitting you to realize a fruitful establishment.

Planning for the Association

Some time recently beginning the establishment, it is basic to accumulate all the essential instruments and materials. These ordinarily incorporate copper channeling, a pipe cutter, a pipe bowing apparatus, a torque, plumbing tape, and a appropriate joint or fitting to put through the copper pipe to the towel rail. The primary step is to turn off the water supply to anticipate any inadvertent water spills amid the method. This guarantees simply work in a dry environment, making the method more secure and simpler.

Once the water supply is turned off, you ought to carefully arrange the arrangement of your towel rail and where the copper pipe will run to associate it. It’s vital to degree and guarantee that the copper pipe is cut to the right length to reach the towel rail.

Cutting and Shaping the Copper Pipe

The another step in how to associate a copper pipe to a towel rail is cutting and forming the copper pipe. Employing a pipe cutter, carefully cut the copper pipe to the length you would like. If there’s a require for twists within the pipe to reach the towel rail, you’ll use a pipe twisting device. Make beyond any doubt the twists are smooth which the pipe is shaped to fit perfectly into the association focuses of the towel rail.

Once you’ve cut and bowed the pipe, check the ends for any burrs or harsh edges. Utilize a deburring apparatus to smooth out the edges, guaranteeing a clean and exact association after you connect the pipe to the towel rail.

Connecting the Pipe to the Towel Rail

At this organize, you’re prepared to connect the copper pipe to the towel rail. Depending on the sort of towel rail and the specific foundation arrange, you will ought to utilize compression fittings or fix joints to relate the pipe. For compression fittings, basically slide the fitting over the conclusion of the copper pipe, guaranteeing it fits cozily. Use a torque to fix the fitting safely onto the towel rail, ensuring there’s no movement or extricating over time.

In case you’re employing a patch joint, you’ll ought to apply warm with a blowtorch to dissolve the patch and make a solid bond between the copper pipe and the towel rail. Make beyond any doubt to take after the manufacturer’s informational for the particular patch joint you’re utilizing to guarantee a watertight association.

Fixing and Testing the Association

After connecting the copper pipe to the towel rail, it’s time to seal the association. To maintain a strategic distance from spills, wrap plumbing tape around the strings of any associations some time recently fixing them assist. Once everything is fixed, it’s pivotal to test the association by turning the water supply back on and checking for any spills. On the off chance that you take note any spills, turn off the water instantly and check the fittings, making beyond any doubt they are legitimately fixed.

After affirming that there are no spills, the connection is secure, and your towel rail is prepared for utilize. The copper pipe will presently give hot water to the rail, warming your towels effectively.

Conclusion

How to associate a copper pipe to a towel rail includes a direct however precise process that guarantees a secure and functional establishment. By following the steps of planning, cutting, forming, joining, sealing, and testing, you’ll be able effectively total the establishment. Whether you are a DIY devotee or a proficient handyman, these steps will direct you toward accomplishing a consistent association for your towel rail, guaranteeing a warm and comfortable washroom encounter.